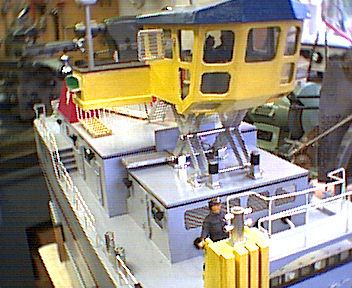

| John Richardson - Pusher tug - Egrete |

|

|

|

The timber frames and strakes were constructed using timber recovered from the carcass of redundant kitchen cabinets. The material used ( some years ) ago was knot free high quality pine and could be ripped to size on the band saw and subsequently planed to size. The joy being that the material cost nothing, except my labor, that is ! The ply was marine quality 1.5mm ply from the local model shop. |

|

|

|

The hull is of rectangular section throughout with only a small amount of bending of the strakes required at the bow, almost like building an inverted box ! |

|

|

|

With the frames erected and true the strakes were installed using brass pins and PVA adhesive, bought by the 4.5 liter container. It is always useful around the house and come in at about 1/3 the price or less than the small bottles in which it is otherwise sold. In passing it is far more economic to buy hot glue sticks by weight at a building supply store than in the bubble pack at DIY or model shops. As soon as frames and strakes were completed hardwood blocks were installed as the bases for the motor mounts, also ply gussets in the sloping section where the propeller shafts pass through the hull. The hull bottom sheeting was commenced, and the motors and propeller shafts installed. Vertical alignment of the motors and shafts was simple as it was possible to sight the alignment through the unsheeted sides of the hull. Bottom sheeting completed by persuading the ply around the gentle upsweep at the bow. |

|

|

|

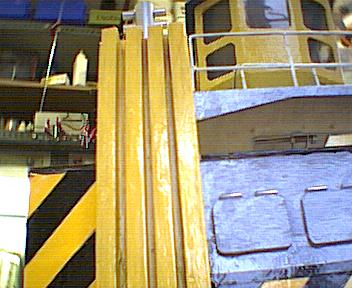

Substantial rails were

inserted to allow firm fixings for the push posts to be added later. This

has since proved to be a wise move as these posts take impact loading when

coupling to a load At this stage the hull was severed from the building boar, always an exciting moment.. With only the bottom sheeting installed the structure proved to be extremely rigid, such that all further sheeting and installation could be carried out without any distortion of the hull. Of course the deck beams already existed as part of the frames and it was only necessary to remove the parts that interfered with superstructure location and access an to trim these with more ' Kitchen cabinet material ' Side sheathing and decking were again simple operations due to the box section of the hull. The overall design of the vessel permits the superstructure to be constructed integral with the hull and deck, avoiding problems with water ingress in ' Heavy weather ' Decking throughout the hull and superstructure is flat, again simple to install, first though the push post, sawn from hardwood, must be securely screwed in place from within the hull. |

|

|

|

Superstructure front and sides were reinforced with strip wood, placed to provide support for the upper decks. Miscellaneous fixings and fixtures were added from ply and styrene sheet to complete the overall appearance. Painting included shellac sealer, primer, undercoat and two coats of Dulux ! |

|

|

|

|

|

|

|

The cable guides on the foredeck were built from brass rod and sheet brass, the decision taken at this stage to fill in the cable ports ( unlike those on the prototype ) has proved to be a wise step in view of the water that washes up the square bows at speed. |

|

|

|

Stacks are from ply. The

companionway which accommodates the rise and fall of the bridge deck from

brass strip and rod, and the railings from brass rod too. Bollards are

from styrene, as is the dory complete with the outboard motor. The crane

and fold down mast are from brass tube, the parts again soldered. The

styrene sheet used for the dory was recovered from the bottom of a Walls

ice cream carton, the source of material for many of the buildings on my

model railway…… economy again !

Brass sheet was bent around a coke bottle used as a former and soldered up to make steerable 'Kort ' type nozzles around the fixed propellers. The steering servo is mounted under a hatch which supports the hawser baskets, also the anchor winches and chain troughs. The shafts of the anchors are within tube supported from the hull by bolted brackets. The anchors are again soldered from tube and plate, in practice they are extremely important as they are used to anchor the vessel against the pull of the winches in the winch house at the bow. Having lost an anchor in a collision on the water the model now has a protective rail around the anchors just above water level. |

|

The pusher was completed by the addition of restraints for the 6V 12Ah Battery, the Msonics digital speed controller and the Action multiswitch ( installed with future working features in mind ) On the water the model is a joy to operate, steering is precise and immediate, the two 480 motors providing more than adequate power and speed. The unusual nature of the boat causes a lot of interest although many people are puzzled by the shape and think that it is some sort of ferry ! All in all, simplicity of build and excellence of performance make the Rhine pusher an extremely rewarding model in all respects. Regards, |